Clamping Principle Of Toggle Latch

Views : 807

Update time : 2020-06-28 12:15:39

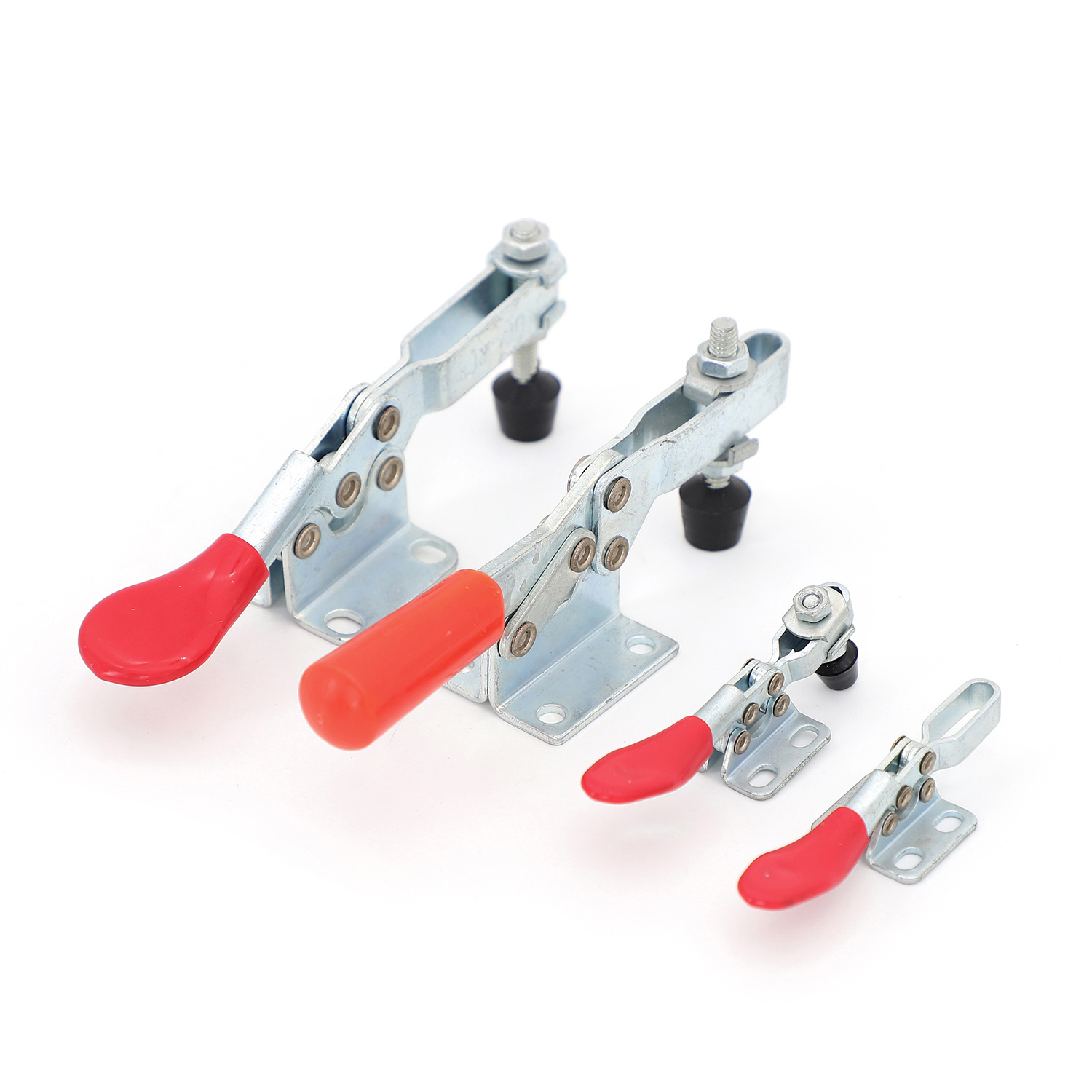

This kind of type of manual toggle clamp is designed according to the mechanical principle of the double rocker mechanism in the plane four-bar mechanism. Its basic structure is composed of four components, such as connecting rod, frame, and two connecting rods.

When the connecting point between the connecting rod and the connecting rod is the two hinge joint and the connecting point between the connecting rod and the frame, the three points are in a straight line, and the mechanism is at the dead center position. At this time, the pressed workpiece, no matter how large the reaction (except destructive force), can not let the head loose. This is the principle of dead point clamping in mechanical mechanics.

In order to avoid the effect of load change and mechanical vibration in use, the connection of the middle hinge is slightly offset to the inside of the other two hinge connections in design to ensure that the clamping mechanism is always locked in the stable state without loosening in the case of the maximum clamping force. The clamping force refers to the maximum pressing force of the head to the workpiece under the lock position without mechanical deformation, which is produced by the press head up to the nearest position of the distance mounting seat. The pressure of the indenter on the workpiece is not constant. It varies with the different positions of the pressure head on the arm, and the clamping force decreases when it is away from the mounting base.

Characteristic

The structure is simple and easy to install.

It is fast handling and easy to operate by the clamping workpiece.

All parts are electroplated and antirust, and the surface is clean and beautiful.

For heavy-duty fixtures, the key parts are heat-treated and have high strength and wear resistance.

When the connecting point between the connecting rod and the connecting rod is the two hinge joint and the connecting point between the connecting rod and the frame, the three points are in a straight line, and the mechanism is at the dead center position. At this time, the pressed workpiece, no matter how large the reaction (except destructive force), can not let the head loose. This is the principle of dead point clamping in mechanical mechanics.

In order to avoid the effect of load change and mechanical vibration in use, the connection of the middle hinge is slightly offset to the inside of the other two hinge connections in design to ensure that the clamping mechanism is always locked in the stable state without loosening in the case of the maximum clamping force. The clamping force refers to the maximum pressing force of the head to the workpiece under the lock position without mechanical deformation, which is produced by the press head up to the nearest position of the distance mounting seat. The pressure of the indenter on the workpiece is not constant. It varies with the different positions of the pressure head on the arm, and the clamping force decreases when it is away from the mounting base.

Characteristic

The structure is simple and easy to install.

It is fast handling and easy to operate by the clamping workpiece.

All parts are electroplated and antirust, and the surface is clean and beautiful.

For heavy-duty fixtures, the key parts are heat-treated and have high strength and wear resistance.

Related News

Read More >>

Huiding Hardware successfully participated in the Russian Industrial Exhibition

Huiding Hardware successfully participated in the Russian Industrial Exhibition

Jul .21.2023

Huiding Hardware had participated in the industrial exhibition in Yekaterinburg, Russia from July 10th to 13th, 2023. The main exhibited products include buckles, clamps, hinges, handles, indexing pins, and stamping parts.

Toggle latch material and finish

Toggle latch material and finish

May .06.2022

Zinc Plated Iron

Nickle Plated Iron

Stainless Steel 304

Stainless Steel 316

Nickle Plated Iron

Stainless Steel 304

Stainless Steel 316

English

English  Deutsch

Deutsch  Français

Français  Русский

Русский  Português

Português